HS-12 Thermal Stripper

- Features

- Documents

- Comments (0)

- Request for Quote

-

HS-12 Thermal Stripper

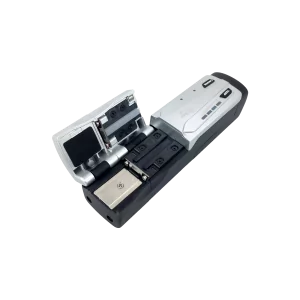

FeaturesThe HS-12 from FiberFox is the world's fastest thermal stripper used for stripping cable jackets in the fusion splicing process. FiberFox HS-12 can heat strip a single and multiple (ribbon) fiber cables in 4 seconds. In additions, it has a long lasting battery, enough for 500 strips.

HS-12 Thermal Stripper Specifications

Fiber MaterialSilica glassCoating MaterialUV cured resinCoating Thickness“Single fiber: 0.25~0.4mm 2 to 12 Ribbon fiber: 0.3~0.4mm”Cladding Diameter125μmCoating Removal Lengthmax 30mmHeating ModeNormal mode / Power save modeTemperature SettingsNormal mode: approx. 80℃, 95℃, 110℃, 130℃

Power save mode: approx. 70℃, 80℃, 95℃, 110℃Fiber Holder TypeFH-2, FH-4, FH-6, FH-8, FH-10, FH-12, FH-250, FH-900Power Supply MethodAC drive: AC100~240V, 50/60HzOperating ConditionTemperature: 0℃~40℃ / Humidity: 0%~95%Applicable Fiber TypeSingle fiber: 250μm, 900μm, 3.0mm fiber cable and flat cable

Ribbon fiber: 2 to 12 ribbon fiber cableHeating TimeApprox. 4~5sec at normal mode

Approx. 5~6sec at save modeBattery CapacityApprox. 500 stripping with 12 ribbon fiber with a full charged batteryHow to Use a HS-12 Fiber Optic Thermal Stripper

-

Turn on The Stripper

Switch the HS-12 thermal stripper on, and never forget to adjust the thermal strippers settings. Different types of fibers require different settings and temperature.

Switch the HS-12 thermal stripper on, and never forget to adjust the thermal strippers settings. Different types of fibers require different settings and temperature. -

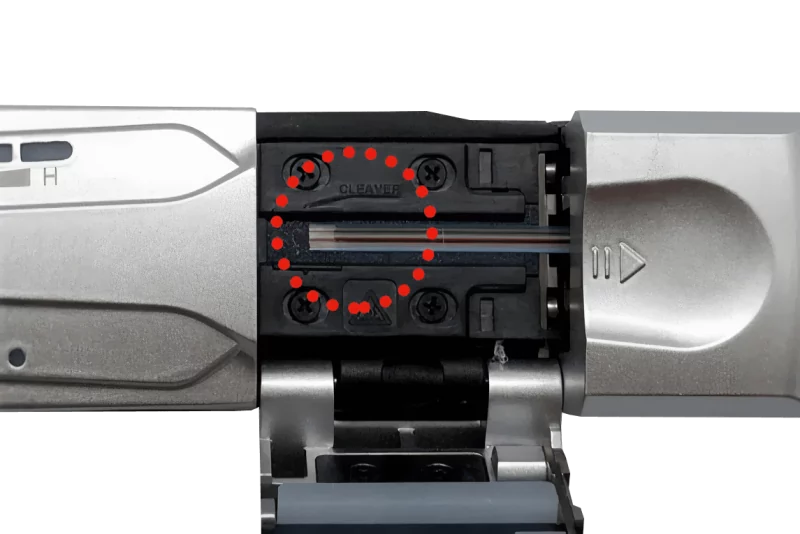

Place The Fiber

Move the thermal stripper's sliding part outward until it cannot be pulled anymore. Open the sliding part cover and the heater cover, and place the fiber with its holder in the sliding part.

Move the thermal stripper's sliding part outward until it cannot be pulled anymore. Open the sliding part cover and the heater cover, and place the fiber with its holder in the sliding part. -

Close the Slider Cover

Close the sliding part cover with the fiber holder inside it.

Close the sliding part cover with the fiber holder inside it. -

Slide Inward

Slide the fiber holder part toward the thermal heater, with its cover closed. Keep the heater cover open to look and make sure you slide until the fiber length is accurate.

Slide the fiber holder part toward the thermal heater, with its cover closed. Keep the heater cover open to look and make sure you slide until the fiber length is accurate. -

Close Heater's Cover

Close the thermal heater cover and it will start heating automatically. You will have to wait until the temperature light starts to blink.

Close the thermal heater cover and it will start heating automatically. You will have to wait until the temperature light starts to blink. -

Pull Slider Outward

After you see the temperature light blinking, hold both covers tightly and pull the slider away from the thermal heater. The heated coating will be removed and the fiber will be stripped and ready for cleaving then fusion splicing.

After you see the temperature light blinking, hold both covers tightly and pull the slider away from the thermal heater. The heated coating will be removed and the fiber will be stripped and ready for cleaving then fusion splicing.

-

About Samm Teknoloji

Fiber Optic Cable Manufacturer

Being a Turkish fiber optic cable manufacturer and an efficient supplier for Europe, Asia and America, SAMM Teknoloji joined the global market with very high potential. SAMM designs and manufactures a wide variety of fiber optic cable types optimized for fixed or mobile networks that can be used in indoor and outdoor environments. SAMM offers reliable, cost-effective optical products to meet the needs of customers with innovative products developed and tested in accordance with international standards.

Fiber Optic Assemblies Producer

As a fiber optic cable assemblies producer and supplier in Turkey and an optical assemblies supplier for Europe and Asia, Samm Teknoloji has been providing high-quality and reliable fiber optic cable assemblies since 2006. Due to our fully equipped production facilities, laboratories and long-term expertise in fiber optics, we are able to produce a first class fiber optic assemblies portfolio that ensure the highest level reliability. Therefore, one of the main priority is the ongoing expansion and advancement of the manufacturing capabilities.

Data Center Solutions Producer

As a Turkish producer of future-ready fiber optic data center equipment, SAMM Teknoloji produces UHD ultra high density MTP/MPO panels and cassettes, modular panels and cabling raceways. SAMM Teknoloji has also kept pace with the accelerating spread of Cloud Computing, which has increased the need for mega Data Centers. SAMM provides Data Center solutions and products that suit all structures with high data storage density, data traffic and data security.