FiberFox Fusion Splicer Devices are made with a lot of attention to accuracy, efficiency, durability and usability. That is why, Samm Teknoloji has signed an agreement with FiberFox Inc. for selling their line of fiber optic Fusion Splicer Devices and hand tools. The main products FiberFox are Fusion Splicer Devices, cleavers, and thermal strippers; and they will be available for order on the Telecom Samm website.

About FiberFox Inc.

Fiberfox Inc. is a Korean company that was founded in Dae Jeon, in 2013. The first flagship fusion splicer of FiberFox was the Mini 6S. It was developed, in collaboration with researchers at the Daeduk R&D complex, in 2011. The engineers in FiberFox have a lot of experience in fieldwork and in research and development. All the Fusion Splicer Devices of FiberFox are made with with high accuracy, efficiency, durability and usability.

FiberFox Fusion Splicer Devices and Hand Tools

Accuracy of FiberFox Fusion Splicer Devices

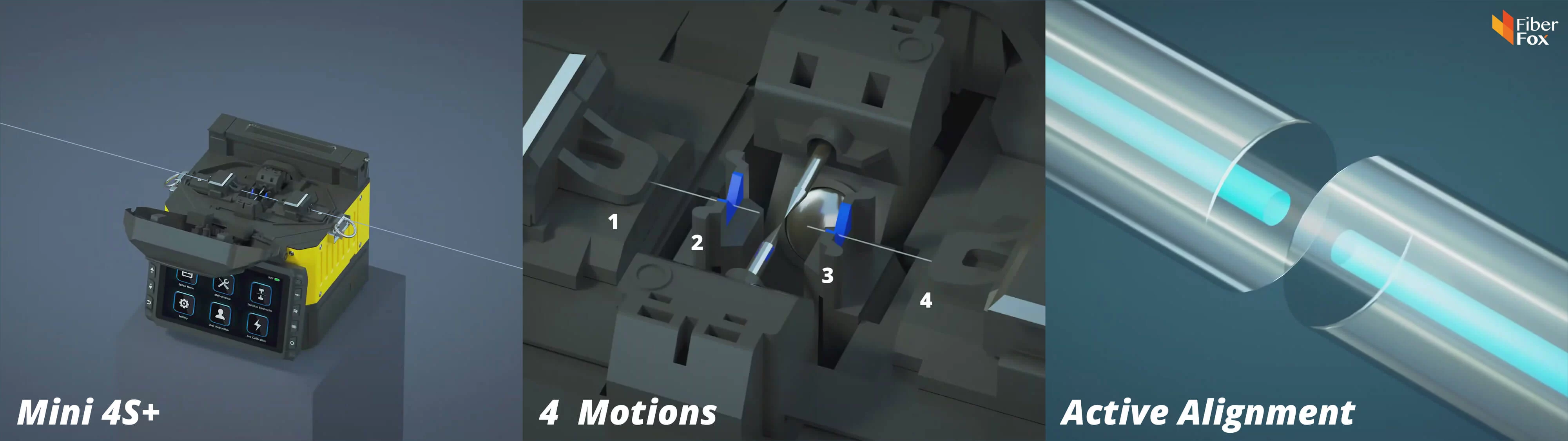

Each one of their fusion devices have well suited alignment technology, such as the active alignment on the 4S+ fusion splicer. 4S+ uses 4 motors to align the splice fibers in 3 dimensions.

The 5C+ fusion splicer on the other hand, uses a digital core alignment technology that zooms the image and calculates the proper position to align the fibers according their inner cores. 5C+ fusion splicer provides a minimal fiber loss level at the point of splicing.

The main flagship device of FiberFox is the 6S+ fusion splicer, which has an automatic optical core analysis and tracking system. The 6S+ splicer optically detects the core positioning in both ends of fibers and automatically finds the ultimate alignment position. 6S+ fusion splicer gives the least amount of fiber loss at the splicing point.

Durability of FiberFox Fusion Splicer Devices

When it comes to durability, the FiberFox Fusion Splicer Devices prove to be an obvious choice. All three splicers, 4S+, 5C+ and 6S+, have a dust proof body for working in harsh field environments. In addition, they are waterproof and can withstand liquid spills and moist environments without breaking down. What also makes FiberFox Fusion Splicers more efficient and durable are the two batteries that come with each device. Using the two batteries the devices can do up to 600 splicing operations, including the heat shrink process of splice protective sleeves. Furthermore, the Lifespan for the splicing electrodes can reach up to 5500 cycles and that makes these splicers very useful in a production line operations.

Efficiency of FiberFox Fusion Splicer Devices

FiberFox Fusion Splicer Devices are very quick and very efficient. The three models of splicers can finish a splicing operation in about 6 seconds, including the alignment process. Likewise, the process of heating the splice protective sleeves on the FiberFox Fusion Splicer Devices is very quick and only takes at most 10 seconds. The heating process can even be less than 10 seconds when using constant heating or micro heat shrink protective sleeves.

Usability of FiberFox Fusion Splicer Devices

The automatic alignment systems and the quick process times, make FibeFox Fusion Splicer Devices very preferable by engineers and production line operators. The less time the splicing process takes the easier the work operation continues. On the other hand, having special compartments allows a FiberFox fusion splicer operator to effortlessly work on fibers that have splice on connectors (SOC). For additional usability, all FiberFox splicers have a tempered glass full touch screen with a handy graphical user interface UI, in order to control the device settings and operation quickly and easily. In addition, the 6S+ has a Wi-Fi compatible version, allowing it to connect to a dedicated phone app easily and upload PDF reports for more detailed analysis of splicing results.

For more detailed info about FiberFox Fusion Splicer Devices and hand tools, you can take a look at the product pages below: